Repurposed Sewing Machine Tables

Old sewing machine tables are a dime a dozen at thrift stores! Don’t pass them by the next time you see them, turn them into something new! Here’s a great way to repurpose sewing machine tables!

Get more painted nightstands ideas here!

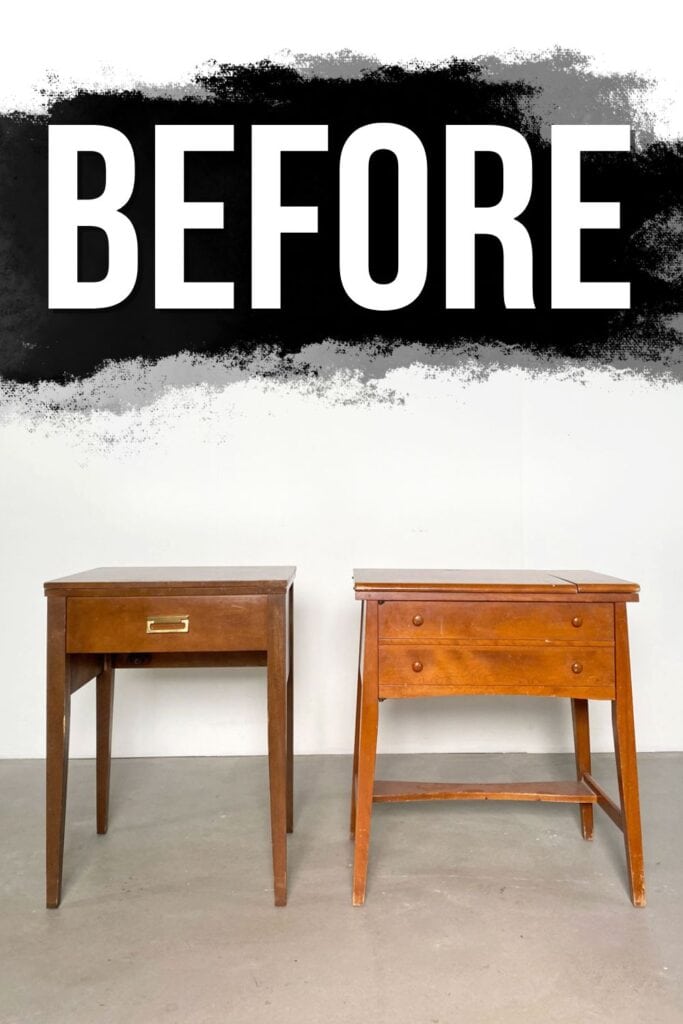

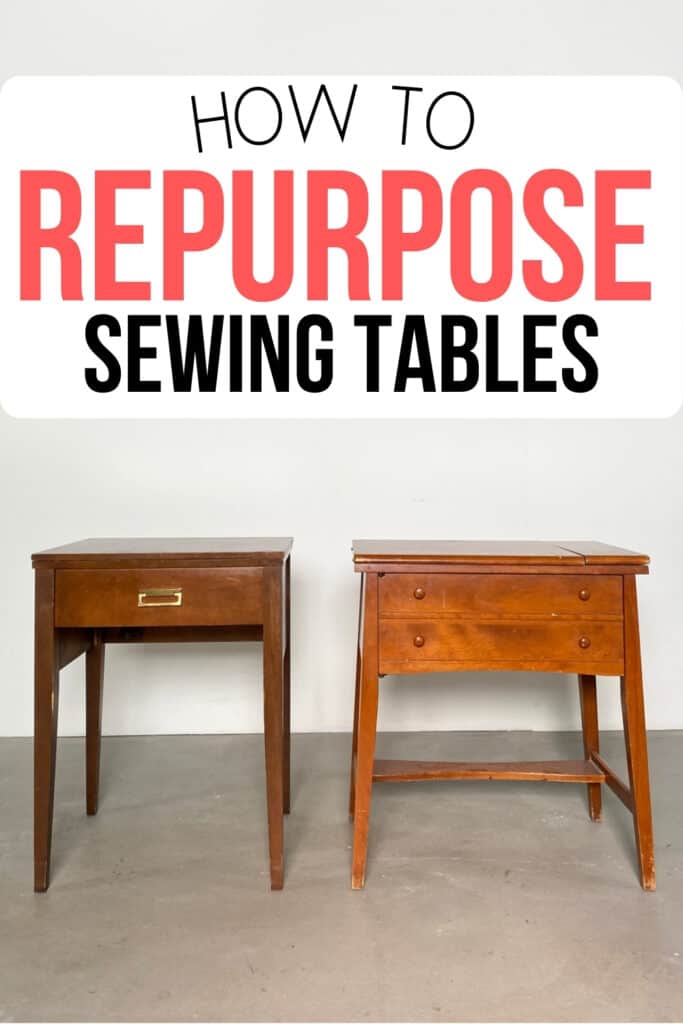

Today I’m sharing how we transformed these old sewing tables with paint that I haven’t tried before.

We picked these up from a thrift store at different times, and they were such a close match in height that I thought they would be great as a mismatched pair of nightstands.

Supplies Used for Repurposed Sewing Machine Tables

As an Amazon Associate, I earn from qualifying purchases. I also may earn from other qualifying purchases with other companies or get free product to review and use. All opinions are my own.

- Dixie Belle Paint in Spanish Moss

- Mist Bottle

- Chiseled Wedge Paint Brush

- Easy Peasy Spray Wax (didn’t love)

- 3×4 Vacuum Compatible SurfPrep Sander Use code RAY10 to get 10% off your order

- Shop Vac with Hose and Brush Attachment

- Tack Cloth to remove the sanding dust

- The Best Waterbased Polyurethane

- Disposable Gloves

- White Paint for Whitewash

- Krud Kutter Cleaner Degreaser

- Favorite 220 Grit Sandpaper

- Fuji Q4 Paint Sprayer my favorite paint sprayer

- Paint Filters to filter paint into the sprayer

- Electric Screwdriver the easiest way to remove hardware

- KwikWood to fill in hardware holes

- Wood Filler

- Clear Shellac – My favorite primer

- Lint Free Rags

- Respirator for spraying

- Fine Grit Foam Sponge

- 1″x12″ Pine Boards

- Table Saw

- Miter Saw

- Pocket Hole Kreg Jig

- Kreg Jig Screws

- Power Drill

- New Hardware

Removing Table Tops

First things first, I flipped each table over and removed the tops, and pieces that used to hold sewing machines.

If you want to keep the sewing machines though, check out my painted sewing machine table here.

Tops are usually just screwed in from the base with pocket holes, so I just had to find the screws and unscrew them.

I typically would keep the top part of the top, and just unscrew it from the part with a hole, as I did with this repurposed sewing table.

But since the bigger sewing table’s top opened up both ways and had a split down the middle of it, I opted to just completely remove and get rid of the tops.

That way I could put solid, matching tops on both of them. Here’s what they looked like after I removed the tops and all of the pieces inside.

Then, I got ready to paint them.

Preparing Tables for Paint

Check out this post for all the tips you need on preparing furniture for paint.

I removed and set aside the old hardware and the parts that I planned to keep, like this little holder on the inside of the door.

I also cleaned them really well with Krud Kutter to remove any dirt and grime that could make the paint not stick. Get more of the nitty-gritty details on how to clean furniture before painting here!

Then I filled in all of the little holes left over from taking things apart, including the dings and scratches that were all over each piece. I just used regular wood filler for that.

I also filled in the old hardware holes on the one table, since I planned to replace it with a single knob. I used my favorite KwikWood to fill in the old hardware holes.

That stuff dries so hard in about an hour and it’s really easy to use! Learn all about how to use KwikWood here.

Check out this post about filling holes when replacing cabinet or furniture hardware to learn about the different wood fillers and why we use them!

When the fillers were completely dry, I sanded them down smooth, and then I scuff-sanded everything else.

Scuff sanding is just a quick little sanding with 220 grit sandpaper, and it really helps paint to stick to the finished wood. Learn more about the importance of sanding before painting furniture here!

I vacuumed off the dust and used a tack cloth to remove all the dust left behind.

And then I sprayed them both with clear shellac. It’s my favorite clear, stain-blocking primer, that also helps the paint adhere better. Read more about the best primers for painting furniture here!

I let the clear shellac dry overnight, and then I was ready to paint!

Why Prep Work Before Painting is Important

It might look like I go overboard with the prep work, but I want my paint job to last as long as possible. Cleaning, scuff sanding, and priming is how I can ensure that.

But there’s something that is called bleed through, that shows up as orange, yellow, or red spots in your paint. And if you don’t block them with a really good stain blocker, they won’t go away.

So, I like to prevent it from happening before it can even happen. That’s where this primer is really important!

Painting Tables with Dixie Belle Chalk Paint

I decided to try a new to me paint line called Dixie Belle Paint in this mossy green color. Check out my list of the best green chalk paint for furniture here.

I’ve heard great things about it and I wanted to see if all of the hype was true. I thought about spraying it on but decided to test out brushing it on these.

Check out my honest Dixie Belle Paint review here.

How to Thin Chalk Paint to Prevent Brush Marks

So, I poured a little bit of it into a separate container and mixed in some water to thin it out a bit.

Dixie Belle Paint, like most chalk paints, is very thick right out of the can! Check out the top chalk paint brands here.

Once it was thoroughly mixed I moved on to painting! First, I used a misting bottle with some water to lightly mist the surface of the table.

I also sprayed my brush before dipping it into the paint.

It was my first time using this technique to get a brush-free finish, so I might have gone a little overboard on the water at first. So I wiped off some of the water and tried again.

With less water on the surface, the paint went on great! It was easy to brush on, and I could tell that brush marks wouldn’t be an issue when it dried!

I honestly can’t believe that I’ve waited so long to try out this technique to prevent brush marks when using a paint brush!! Here’s more about how to paint furniture without brush marks.

Check out how I sprayed Dixie Belle paint with these chalk painted end tables.

After everything was painted, I let the paint dry completely, which really took less than an hour.

Then I sanded the paint with a fine-grit foam sponge to make extra sure that I wouldn’t have any brush marks. Honestly though, I don’t think I really needed to sand in between coats to ensure a brush-free finish!

Then I vacuumed and wiped off the dust and painted the second coat, just like I painted the first coat.

The coverage was great with just two coats of paint. That’s pretty typical, but I was happy that with all the extra water I used, that I didn’t need a third coat.

Topcoating Paint with Dixie Belle Spray Wax

The next day I came back to topcoat them. Instead of using water-based poly like I usually do, I thought I would keep trying something new.

So I bought Dixie Belle’s Easy Peasy Spray Wax to try out.

It’s water-based, instead of oil-based, like most waxes. So if I didn’t like how it turned out, I knew I could easily go back to my water-based poly that I love.

Read more about some of my favorite polyurethane for furniture here!

I sprayed it on, let it sit for a few seconds, and then I wiped it all over with a lint-free rag.

I love that it doesn’t stink and that it’s water-based! It also dries pretty fast, in only 30 minutes and they say that it is cured in 6 hours!

It was pretty easy to spray on, but honestly, other soft waxes that I have used are just as easy to apply. And I kind of feel like they soak in more than this spray wax did.

My biggest fear though was if it was going to be as durable as I want it to be.

Spray Wax Finish

I just wasn’t in love with the finish that the spray wax created. It was very matte, which meant that every speck of dust stuck to it. And I was worried about how durable it really was.

So, since it’s a water-based product, I went ahead and sprayed a couple of coats of water-based poly over it. Check out this post on how to spray polyurethane for all of my tips!

I just felt better about having a more durable finish on these, especially since I will be selling them. Next time I might try Dixie Belle’s regular wax and see if I like it any better than this spray stuff.

There are honestly so many topcoats for painting furniture!

Making New Table Tops

Since lumber is harder to come by right now, I couldn’t find my usual edge-glued boards that I love to use when I put a new top on things. So I went with a couple of 1 x 12” pine boards instead.

We ripped them down to half the size that we needed and then chopped them down to the length that we needed.

We basically just added an inch to the overall dimensions of each table, so we would have a ½” overhang on every side.

Then I sanded all four pieces with 220 grit sandpaper to get rid of any splinters or rough spots.

And then we joined the boards together with our pocket hole Kreg Jig and screws.

I wanted the tops to look as much like one solid piece of wood as I could, even though each top was really two pieces of wood.

If you like a weathered look, check out how to make a plank top dresser here.

Whitewashing Wood Tops

Then I moved on to finishing the wood. I started by brushing on one coat of water-based poly.

The coat of water-based poly before the whitewash helps the whitewash not soak into the wood so much, so I have a few more seconds to work with it. And so the wood wouldn’t end up super white.

Learn more about how to whitewash furniture here.

How to Make and Apply Whitewash

After the poly was dry, I mixed up a batch of whitewash with some white chalk paint and water.

I honestly don’t measure how much water I put in the paint, but I like it to be pretty thin, kind of like tinted water.

Then I quickly brushed on the whitewash and wiped the excess off with a lint-free rag.

The point of the whitewash was basically to lighten up the pine so that it would look kind of like raw wood when I sealed it for the final time.

So I really just wanted a really really light coat of white. When the whitewash was dry, I lightly sanded it with 220 grit sandpaper to smooth the wood down a bit.

See how we used this whitewash method in this DIY whitewash dresser makeover! Check out more whitewashed furniture ideas here.

And then I sealed it with 3 coats of water-based poly to protect the wood.

Attaching New Tops to Tables

The next day, we put the new tops onto the tables.

I laid down a blanket to keep the top from getting scratched, and I marked the back of the top so I knew where to place the bottom of the table.

And then, while my husband put some weight on the table to hold it in place, I screwed some new pocket hole screws in the pocket holes and into the new top.

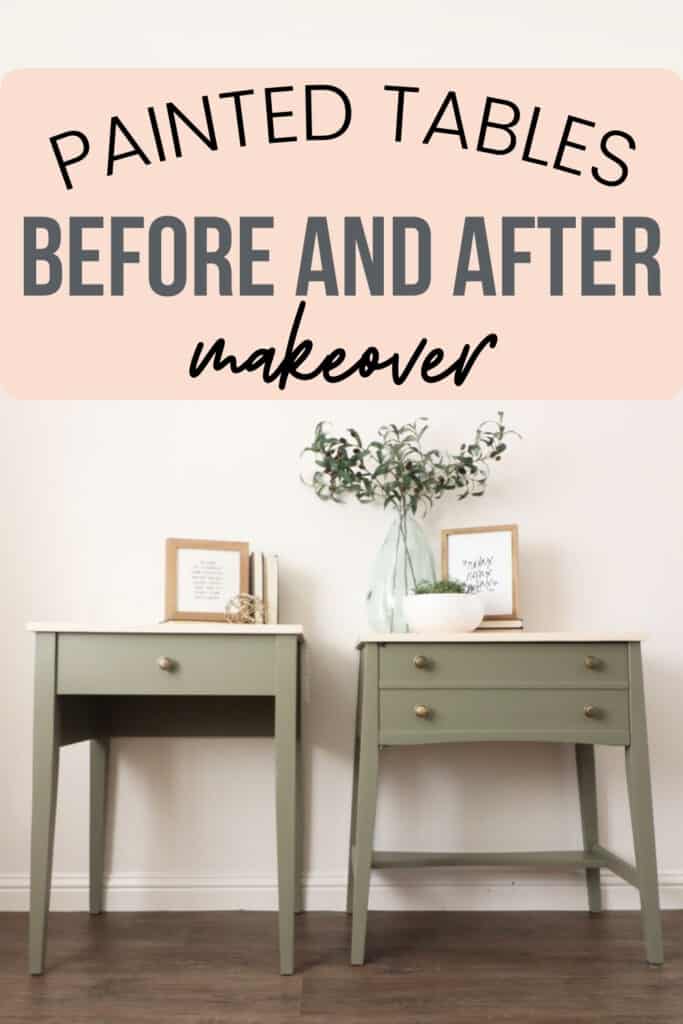

Then I put everything back together and was done! Check out more mid century modern painted furniture for inspiration here.

Here’s the full makeover video if you’re a visual learner!

And here’s what they look like now!

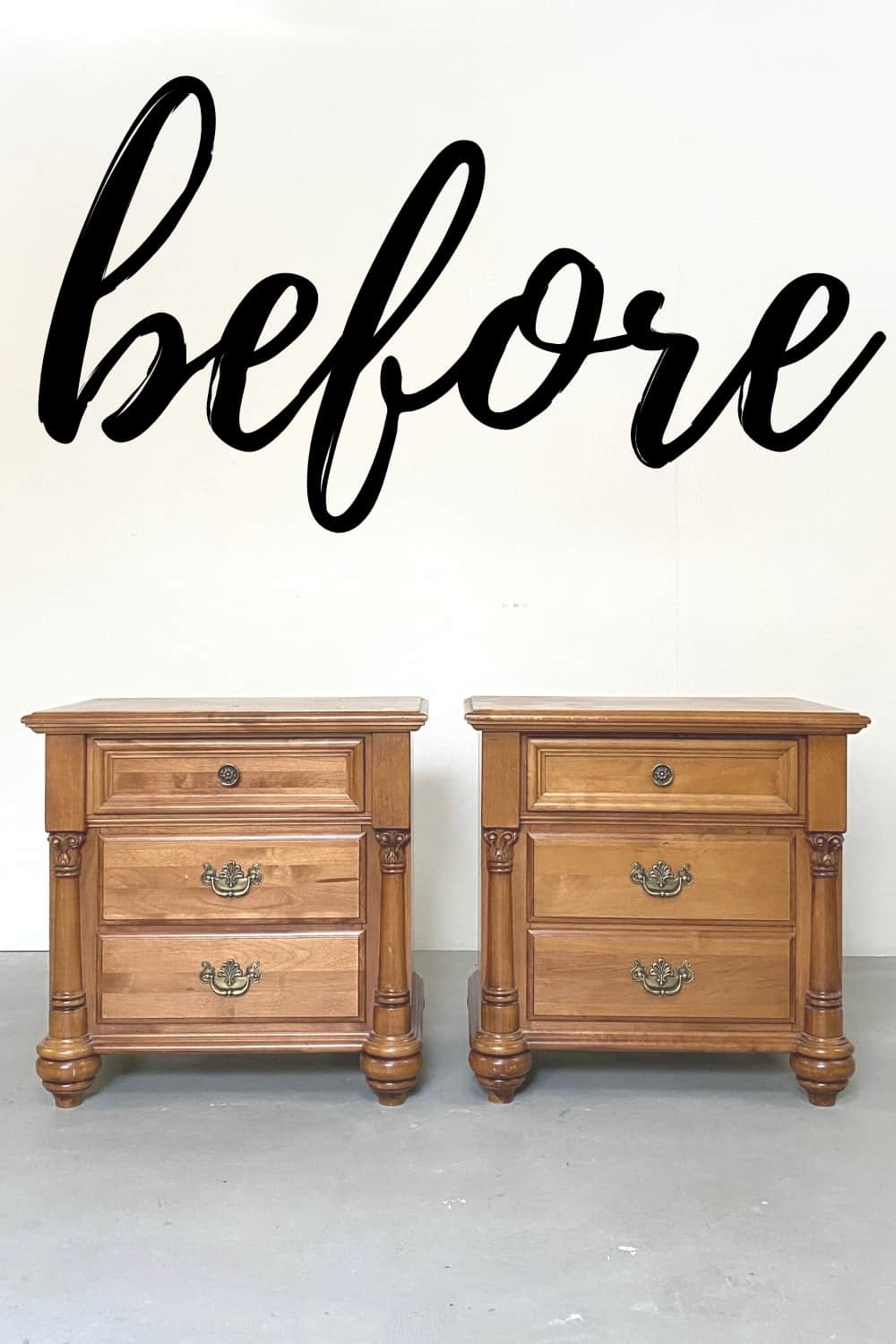

More Before And After Makeovers

Click any of these “before” photos below to view the “after” of that makeover.

They both started with a modern vibe but were completely different at the same time. Matching paint, tops, and hardware brought them on the same level to make them a pair!

Are you a fan of mismatched furniture?!

More Repurposed Furniture Makeovers

- How to Repurpose Desks

- Repurpose a Desk into Nightstands

- How to Upcycle a Desk into a Pair of Nightstands

- How to Make a Bench from a Headboard and Footboard

- Turning a Dresser into a TV Stand

Follow us on YouTube to get more tips for painting furniture.

Or share your project with us on our Facebook Group and be part of our community. See you there!

I have the same exact sewing table as the one on the left. I just might hold onto it instead of getting rid of it now that I have seen the possibilities!

This is a great idea! I have an old sewing machine that I don’t use anymore, and I could definitely use a new side table. I love that you can still see the sewing machine parts on the table – it’s a great