How to Sand Down Wood

If you’ve ever wondered how to sand down wood to prepare for refinishing furniture, you’re in the right place! This blog post is designed to take you step-by-step through the process of sanding furniture to raw wood, whether you’re dealing with veneer or solid wood.

From understanding the type of wood you’re working with, to the correct sandpaper to use, and even tips on sanding techniques – we’ve got it all covered.

Sanding wood can seem like a daunting task, especially if you’re new to it. But don’t worry! Whether you’re sprucing up a beloved piece of furniture or working on a DIY project, this guide is here to help.

Packed with handy tips and proven techniques, this post will show you how to sand wood like a pro. So let’s dive in, dust off those old pieces, and give them a fresh new life!

supplies for sanding down wood

As an Amazon Associate, I earn from qualifying purchases. I also may earn from other qualifying purchases with other companies or get free product to review and use. All opinions are my own.

Is Your Wood Veneer or Solid Wood

First, make sure you know if you are working with wood veneer or solid wood.

Some wood looks like it’s a solid piece of wood but really it is just a thin piece of wood put over another type of wood whether it be particle board or real wood. Veneer is just a very thin piece of wood and it is easy to sand through it and down to the next layer.

It’s important to figure out if your wood surface is a veneer or a solid piece of wood before you start sanding, then you know how aggressive you can be with sanding.

How to Identify Veneer Wood

How can you tell if wood is a veneer? Well, on the edges of your furniture or the edges of your piece of wood, usually you can see a very thin dark line where the veneer is on top.

In the photo above, the veneer is a laminate veener instead of wood, but the look from the side looks the same!

It usually is like a sixteenth of an inch thick and it just looks different than the rest of the wood on the sides. If you can’t see this on your furniture, usually you can see this on the back, but sometimes they also put veneers on the edges as well.

And so sometimes it’s nearly impossible to tell if it is a piece of veneer. Just remember, even if it might kind of look like it’s not a veneer, it very well could still be veneer.

So be careful and don’t sand too aggressively because you might sand through the veneer and if you do sand through the veneer, then it will be almost impossible to stain that wood and make it look good.

If you’re wondering: can veneer be sanded? The answer is yes, but you have to be cautious, check out this post to learn more.

Or if you found out that there is a particle board below the veneer layer and you want to fix this issue here’s sanded through veneer to particle board!

Preparing for Sanding

First, make sure that your wood surface is clean. If it is a finished wood surface with a stain on it and it has been used, make sure that there’s not grease or grime, or wax on the surface that can get smushed into the wood grain when you are sanding.

With a degreasing cleaner like Krud Kutter and a damp rag to remove the oils and the grease and the grime. Let the wood dry completely. Here’s our step by step guide on how to clean furniture before painting.

Once you know if you’re working with veneer or a true piece of solid wood then you can decide what your plan of attack is.

If you’re working with a piece of veneer and you want to sand the old finish off of it, my recommendation is to first use a chemical stripper to remove most of the old finish and then sand down the wood.

Learn how to use a chemical stripper in our posts on how to remove wood Stain or our post on how to remove paint from your old wood furniture.

Chemical strippers will just remove the stain and the finish from your wood and they will not ruin the wood or go through the wood veneer.

And when it’s time to sand the wood all you will have to do is just a light sanding and you won’t have to worry about sanding through thin wood veneer. Here are the best wood stain removers to remove the old finish before sanding.

If your wood is a solid piece of wood with no veneer on it you can sand to your heart’s content because usually that wood is pretty thick and you don’t have to worry about sanding too much on that.

Sanding Process

When you are sanding down to bare wood, start with coarse grit sandpaper. Something like 80 or 100 grit sandpaper will work really well and fast at removing the stain or the paint that is on the wood.

It will also do a very good job of sanding the wood down to remove scratches and nicks and get most of it off.

If you don’t have a power sander, do yourself a favor and invest in one! Your project will go by much faster if you have even a budget friendly sander in your toolbox! Here are the types of sanders for furniture if you aren’t sure what sander to get.

The Importance of Sanding with the Grain

Remember when you’re sanding to sand with the direction of the wood grain which are those lines that are in the wood. For best results, sand with those lines so then you don’t get a bunch of swirl marks left in your wood that show up after you stain.

After you sand with 100 or 80 grit sandpaper, remove the dust from your surface and then move to either 120 grit sandpaper or 150 grit sandpaper.

Progressing Through Sandpaper Grits

Then sand everything down with 120 or 150 grit sandpaper. The point of this is now to smooth out the wood and remove those sanding swirl marks left behind by the very coarse grit of sandpaper.

If you sand with 80 grit and then you go up to 220 grit, you will probably have a lot of sanding swirls in your wood. So, to avoid the sanding swirls, you need to move through each number of grit starting at the lower numbers and working your way up to the higher numbers.

You can skip one number of grit at a time, so for example, you can go from 100 grit sandpaper to 150 grit sandpaper, but you should not go from 100 grit sandpaper to 220 grit sandpaper.

After you sand with 120 grit or 150 grit sandpaper, remove the dust again to help the sandpaper sand faster and more efficiently. Then sand everything with 220 grit to prepare the surface for paint or stain.

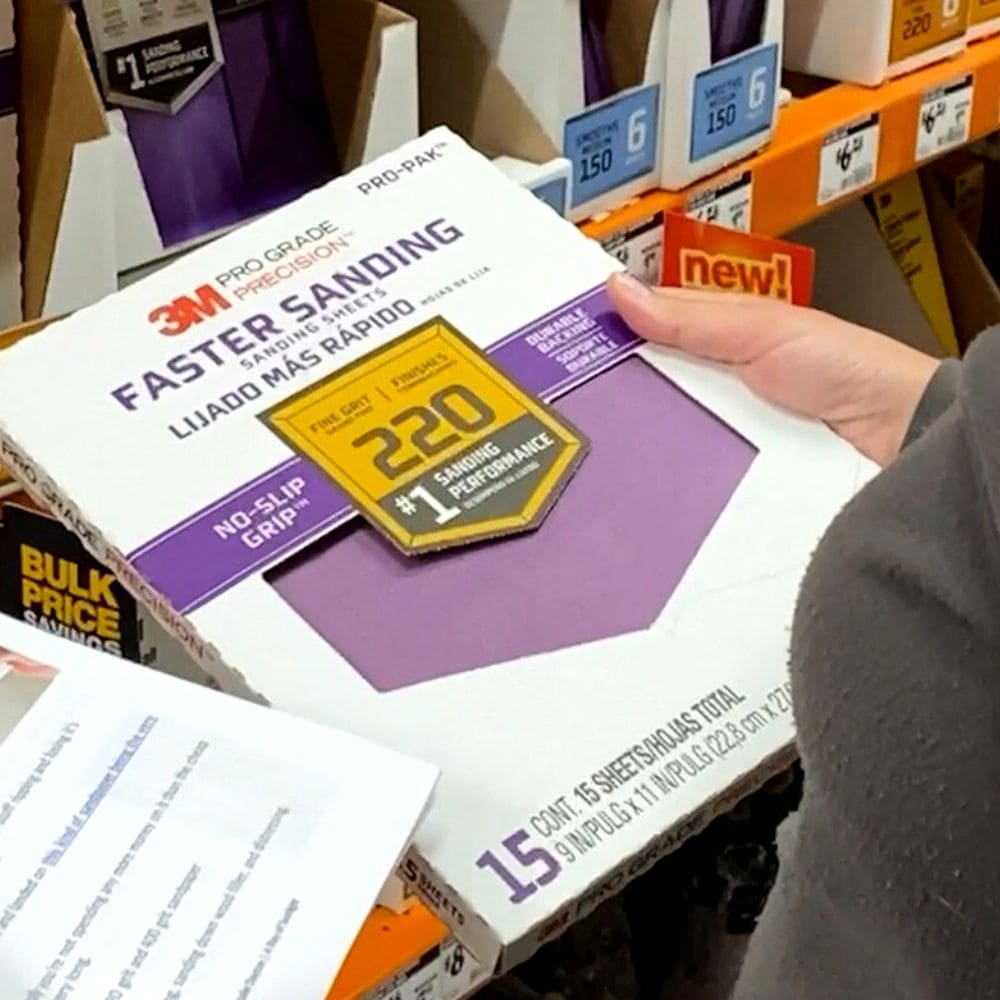

The Best Sandpaper for Sanding Wood

The best sandpaper for sheet sanders or sanding by hand is 3M Pro Grade Sandpaper. It holds up longer than other sandpaper and the abrasive lasts longer than other sandpaper.

If you’re using an orbital round five inch sander, use Diablo sanding discs or sand net discs. The sand net is awesome for sanding and they are really good quality as well because they don’t clog up easily, so it makes the job go faster.

If you are sanding edges or details SurfPrep makes these awesome foam sand sanding pads (Use code RAY10 to get 10% off your order) that will sand your details and your curves. And they make foam sanding pads for electric sanders of all different sizes and shapes.

Any sander that accepts a Velcro or a hook and loop type piece of sandpaper on the sander, SurfPrep has a foam pad for your sander and that will help you sand curved surfaces as well as your details and your grooves a lot easier with a power sander.

For more information on the best sandpaper to use for your project, check out our sandpaper for furniture painting blog post for all the details you need to know before you choose.

We’ve also listed the different types of SurfPrep Sandpaper here which are compatible with most sanders.

And there you have it! Sanding might seem like a daunting task but with the right tools, a good understanding of the material you’re working with, and a dash of patience, you’ll have your wood looking as good as new.

Whether it’s veneer or solid wood, remember to approach with care, follow the grain, and work your way up with sandpaper grits. Happy sanding!

more sanding furniture tips

- Importance Of Sanding Before Painting Furniture

- How to Sand Wood By Hand

- Festool Rotex 125 Review

- Best Detail Sander

- Best Hand Sander for Furniture

Follow us on YouTube to get more tips for painting furniture.

Or share your project with us on our Facebook Group and be part of our community. See you there!